Lamination is the common practice of welding lineal folded steel, typically to achieve homogeneity in the quality of the steel across a sword. Small areas of impurities or other imperfections could add brittleness or other faults that might lead to breakage in battle.

Micro-lamination refers to the folding and re-forging of layers of billets. Sometimes called "Folded Damascene", this technique may use a single type of steel or several types.

Steel that has been laminated for homogeneity will exhibit layers, as with pattern-welded steel. This is true even if the piece is folded from a single initial piece (e.g., as in steel made from springs) instead of piled steel (i.e., billets of steel made separately and then forged together). The nature of the heating process during forging alters the steel alloy at the surface of each billet and this in turn causes visible dividing lines. However, unlike pattern-welded steel or wootz, the steel will require acid etching (possibly many times) before the pattern shows up.

Laminated steel may show thousands of layers, a result of the multiple folding and refolding of the steel. The faint lines may appear as very fine grain fibers arranged linearly along the blade.

Macro-lamination refers to the joining of larger pieces of steel to form a blade.

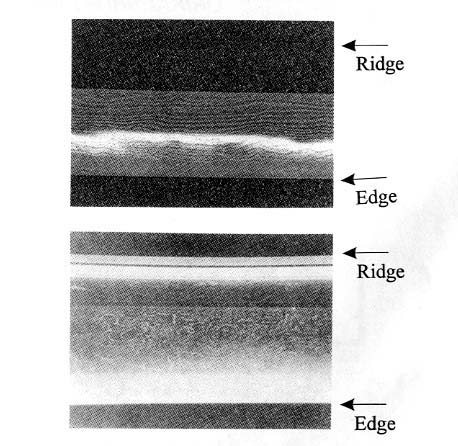

Some swords will show lamination only in the edge, generally a laminated or pattern-welded steel that is inlaid on one side of the blade. This may be done, for example, to provide a particularly hard edge that will remain sharp while a "softer" steel is used for flexibility in the rest of the blade. Sometimes this is done to simply achieve size or a particular shape in the finished blade. Macro-laminated steel is typically made from micro-laminated steel.

Image Source: Quenching Process of Japanese Sword